Stamper Production

The cleaned Glass Master is sprayed with silver nitrate and a reducing solution to create a thin coat of silver. It is then electro-plated with high grade nickel in a two stage process. This gives the metal form rigidity, and it can then be removed from the Glass Master. This is the Metal Master, a negative image.

After careful cleaning the Metal Master is used to ‘grow’ positive masters, or Mothers. This is another electro-forming process. A number of mothers can be made from one Metal Master.

Again after careful cleaning the positive Mother is used to create the Stampers – the final negative image from which the videodiscs are pressed.

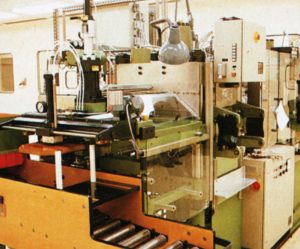

Disc Pressing

A pair of Stampers (Side 1 and Side 2) are placed in the press. The electro-conductive plastic compound from which the disc is made is extruded in a semi-liquid state into a carefully regulated form, known as a Patty. This is transferred to the space between the stampers, and as the press closes. steam is injected.

A pair of Stampers (Side 1 and Side 2) are placed in the press. The electro-conductive plastic compound from which the disc is made is extruded in a semi-liquid state into a carefully regulated form, known as a Patty. This is transferred to the space between the stampers, and as the press closes. steam is injected.

When the Patty has spread out cold water replaces the steam — the compound solidifies, and a videodisc emerges.

The disc is edge-trimmed, proceeds through quality assurance, and is then placed into its protective plastic disc case.